My large Kossel variant has been running for several years now. It is reliable and produces good prints. I have however replaced the extruder drive and the power supply by different models, and added a filament monitor. I will now describe these changes and the reasons for them.

Extruder drive

This machine originally used a hinged variant of the printed extruder used in the RepRapPro Ormerod 3D printer. I found that extruder reliable and easy to use. The hinged nature made loading filament especially easy. However, I felt that it was time to try something different and also to choose an extruder drive that was readily available and didn’t require a good 3D printer to fabricate. I chose the E3D Titan.

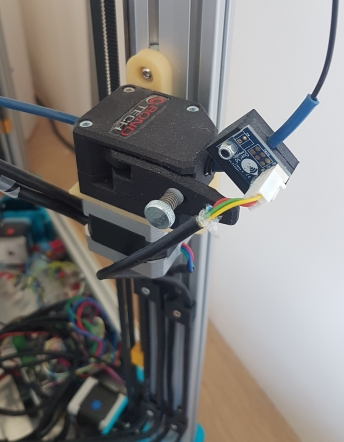

Unfortunately the Titan didn’t live up to my expectations. It jammed several times, and sometimes when it jammed I had to disassemble the Titan in order to feed new filament through it. So I decided it was time for a change. My choice was the Bondtech BMG extruder (standard, not mirrored).

The Titan was mounted on the rear vertical extrusion to keep it out of the way, but that made it difficult to get at. So I decided to mount the BMG on the front right extrusion instead. To keep it looking neat I designed and printed some new cable clips. The extruder mounting bracket that I had printed for the Titan didn’t need to be changed for the BMG.

The BMG extruder has been very reliable, so I recommend it as an upgrade for anyone who has been struggling with the Titan.

Filament monitor

Following the introduction by Prusa of a laser filament monitor, Duet3D produced a filament monitor using the same laser sensing chip but with a robust interface back to the controller electronics, suitable for connecting to a spare endstop input on Duet electronics. Later they produced an alternative filament monitor using a rotating magnet and a Hall angle measurement sensor.

I installed the laser filament monitor on the Kossel. It works by measuring the filament moton and comparing that with the commanded extruder motion. If the difference exceeds a configurable threshold, it pauses the print. It has been working well for me. However, it is known to have difficulty with some types/colours of filament. Prusa found the same problems and discontinued that type of sensor. So for anyone wishing to add a filament monitor to their Kossel, the rotating magnet one is probably a better choice. In either case, the filament monitor needs to be mounted very close to the extruder inlet, so that motion of the filament through the monitor close follows motion of the filament through the extruder.

Power supply

Yesterday while printing I detected a smell of burning, emanating from below the bed. On dismantling the printer, I found a scorch mark on the top of the power supply casing. I removed the cover and found a burned resistor, along with scorch marks all around a toroidal inductor. On removing the inductor, I found the whole PCB area below was scorched.

Yesterday while printing I detected a smell of burning, emanating from below the bed. On dismantling the printer, I found a scorch mark on the top of the power supply casing. I removed the cover and found a burned resistor, along with scorch marks all around a toroidal inductor. On removing the inductor, I found the whole PCB area below was scorched.

So don’t buy a cheap no-name Chinese power supply like I did! I replaced it with a Meanwell LRS-150-24 power supply. Not only does it have a higher rated output (6.5A) than the original (5A), it is also smaller.

What’s next?

Although this printer is very reliable, I am considering some further improvements

- Smaller, lighter hot end

- Flying extruder, possibly mounted on a powered carriage on a 4th tower

- Better print cooling fan and duct

Watch this space!

Hi!

I am right now printing some pieces to star building my own Kossel XL.

Your explanations and BoM has helped me so much.

Congratulations for your work and thank you because your blog is the first step for lot of people 🙂

This is funny timing. I replaced my Titan about a week ago for much the same reason as you. It was a pain to work on. I replaced it with a Flex3Drive, so now flexible filaments will be a breeze. So far, I am liking it a lot.

I am also glad I went with the MeanWell power supply during the initial build. The cheap units are just not worth the hassles, and safety issues, as I learned when building personal computers years ago. Buy once, cry once.

In the middle of a large Kossel Build, Only reasonable source for 2060 only have 500mm long pieces so am going with that for the base. Debating the smart effector or just get the BLtouch unit.

Looked at 3D printing the corners, but it was cheaper to order aluminum rather than filament

Do not use any type of Z probe that is offset from the nozzle on a delta.